Author: admin

News

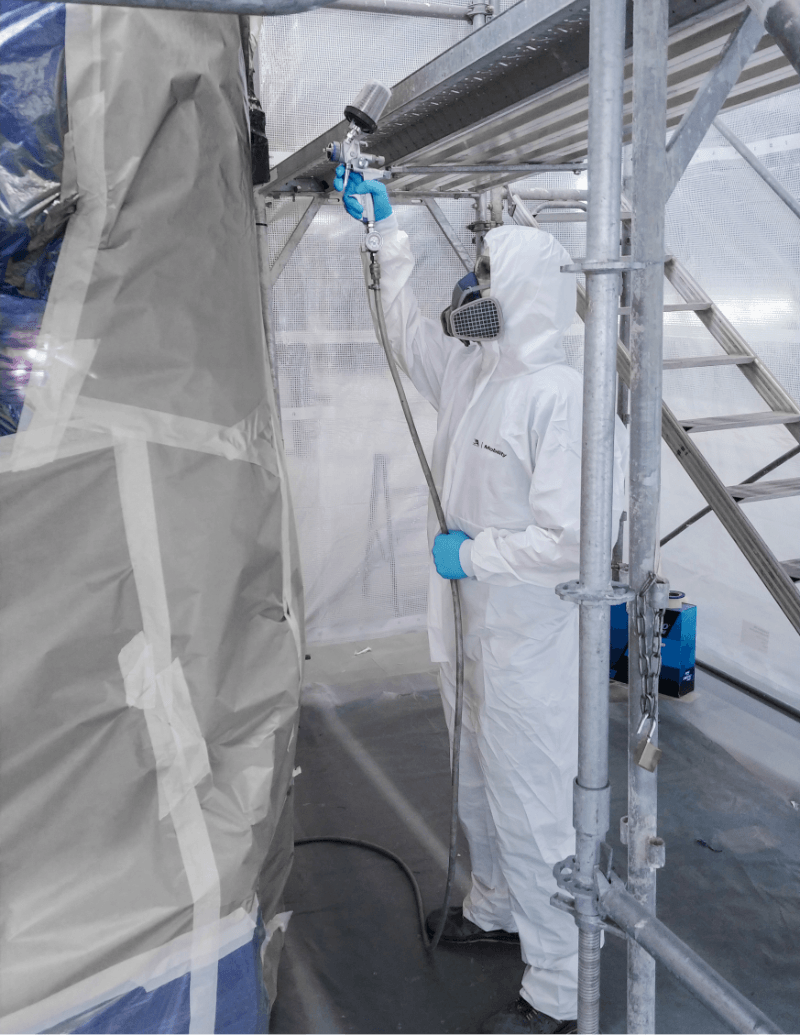

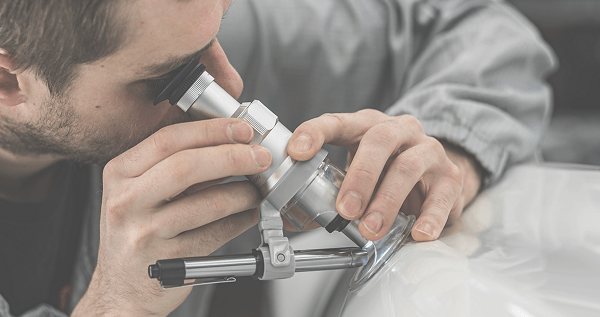

At 3A Composites Mobility, we take care of our customer at every stage. Our goal is to ensure reliability and functionality of our products and solutions. That is why our customer can always expect quick and top-quality service, especially in emergency situations.

What is guaranteed by our service?

- Quick reply to an inquiry

- Field repair option

- Qualified team

- Availability of spare parts

- Up-to-date information on the location of the service crew

- 2 years guarantee on repair service

Scope of services:

- GRP component damage repairs (surface ready for priming)

- Welding in accordance with railway standard EN 15085-2 CL2 and quality standard EN ISO 3834-2: 2005 (according to the customer’s specification)

- Adhesive according to DIN 6701-2/A1 (replacement of vehicle windshields)

- Painting in accordance with technical data (water or solvent based painting)

After each service we provide a detailed report on the work carried out.

What are your benefits?

- Reduction of costs associated with putting a rolling stock out of operation

- Increase of the rolling stock reliability factor

- Preservation of structural and visual properties of GRP elements

- Restoration of full vehicle functionality after servicing or repair

News

At 3A Composites Mobility, we take care of our customer at every stage. Our goal is to ensure reliability and functionality of our products and solutions. That is why our customer can always expect quick and top-quality service, especially in emergency situations.

What is guaranteed by our service?

- Quick reply to an inquiry

- Field repair option

- Qualified team

- Availability of spare parts

- Up-to-date information on the location of the service crew

- 2 years guarantee on repair service

Scope of services:

- GRP component damage repairs (surface ready for priming)

- Welding in accordance with railway standard EN 15085-2 CL2 and quality standard EN ISO 3834-2: 2005 (according to the customer’s specification)

- Adhesive according to DIN 6701-2/A1 (replacement of vehicle windshields)

- Painting in accordance with technical data (water or solvent based painting)

After each service we provide a detailed report on the work carried out.

What are your benefits?

- Reduction of costs associated with putting a rolling stock out of operation

- Increase of the rolling stock reliability factor

- Preservation of structural and visual properties of GRP elements

- Restoration of full vehicle functionality after servicing or repair

News

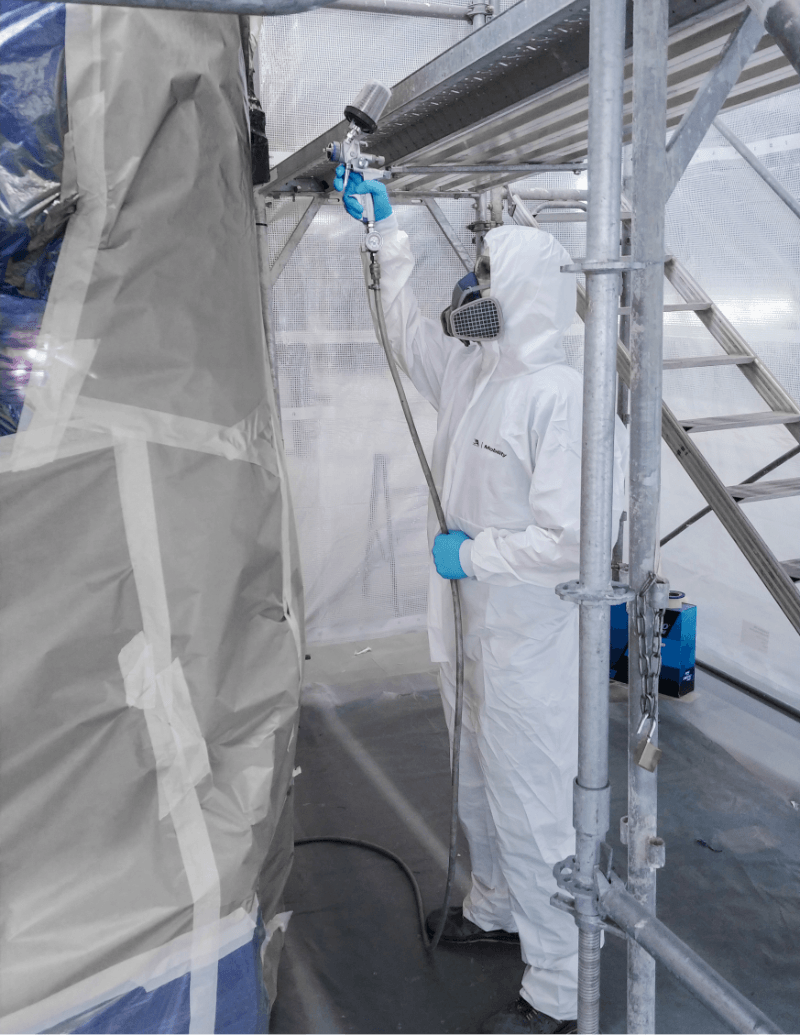

On October 18-23, 2019, the most important bus exhibition in Europe – BusWorld 2019 took place in Brussels. Our company was one of the exhibitors.

At 3A Composites Mobility, we are happy to exchange experiences and present functional solutions that our engineers and constructors are working on. This year at our stand you could see, among others with a group of light external XBODY panels that we designed for road vehicles. They have enjoyed widespread recognition in the industry for many years, which is why we have proudly presented them to such a large audience.

As one of the leaders in the industry, we openly talk about our technologies, which is why each visitor could count on a Q&A session with specialist. The talks concerned, among others roofs and bus chassis, which are an integral part of XBODY. COMFLOOR floor panels were also a popular topic. Participation in BusWorld is a great opportunity for us to not only establish valuable business contacts but to have a real impact on which direction the industry is heading.

The international event, which has attracted tens of thousands of supporters of new technologies since 1971, is an opportunity to learn about the technology for the bus and coach industry that optimizes costs, and significantly increases the safety and comfort of using vehicles.

Thank you to everyone who visited our stand. See you during the next edition!

News

Visit us at BusWorld 2019 in Brussels on 18-23 October 2019

You will find us at Hall 9, Booth 904B

As a forward-looking and future-oriented company, 3A Composites Mobility always want to be up to date with the latest technology and achievements in the bus and coach industry. Above all, however, it is an excellent opportunity for us to present the latest innovative solutions and technologies developed for the transport industry by the 3A Composites Mobility team.

Contact our sale representatives to make an appointment:

Bart Radema

+41 79 671 88 60

bart.radema@3acomposites.com

Andreas Scheiwiller

+41 79 387 03 29

andreas.scheiwiller@3acomposites.com

For further information please contact:

Agnieszka Działo

Marketing Specialist

+48 17 773 78 26

agnieszka.dzialo@3acomposites.com

News

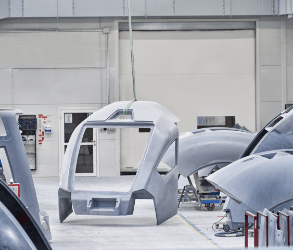

In 3A Composites Mobility we put our effort into the best quality possible combined with the speed and efficiency of production. We enjoy the effectiveness of our activities. That is why we would like to boast that from our production line on 16th May the 100th piece of the FLIRT UK cabin produced for Stadler and the RRX cab for Siemens came off.

It is a great reason for us to celebrate and proof that the daily work of our entire team brings measurable and impressive results. The Management Board of the Company on this occasion invited for a sweet treat, which was prepared in the company’s canteens.

Thanks and gratitude to the employees for their work and joint celebration of the jubilee is the basis of the organizational culture of 3A Composites Mobility.

However, we do not rest on our laurels, but it is even more motivation for us to further spectacular achievements.

News

In 3A Composites Mobility, we constantly develop our technologies – this is why we are pleased to present a new spray booth. The new booth provides the reliability of manufacturing process of INNOCAB®, one of our flagship products.

With the new spray booth, we guarantee:

the highest quality of paint coats

- the 3-stage pre-filtration used in the spray booth ensures the purification of air from various dust

full control at each stage of the painting process

The spray booth features:

- smooth adjustment of ventilation and pressure efficiency,

- heating performed with the use of modulating gas burners with an open combustion chamber, ensuring:

- stable temperature maintenance during painting,

- high drying temperature – up to 95 degrees.

- advanced electronic controller responsible for the efficiency of the humidification system in order to maintain the desired parameters, such as humidity or temperature.

In addition: the correctness of the painting process is taken care of by our highly qualified personnel

environmental safety

- the spray booth is equipped with recuperators and carbon filters reducing the emission of dust, volatile substances and CO2